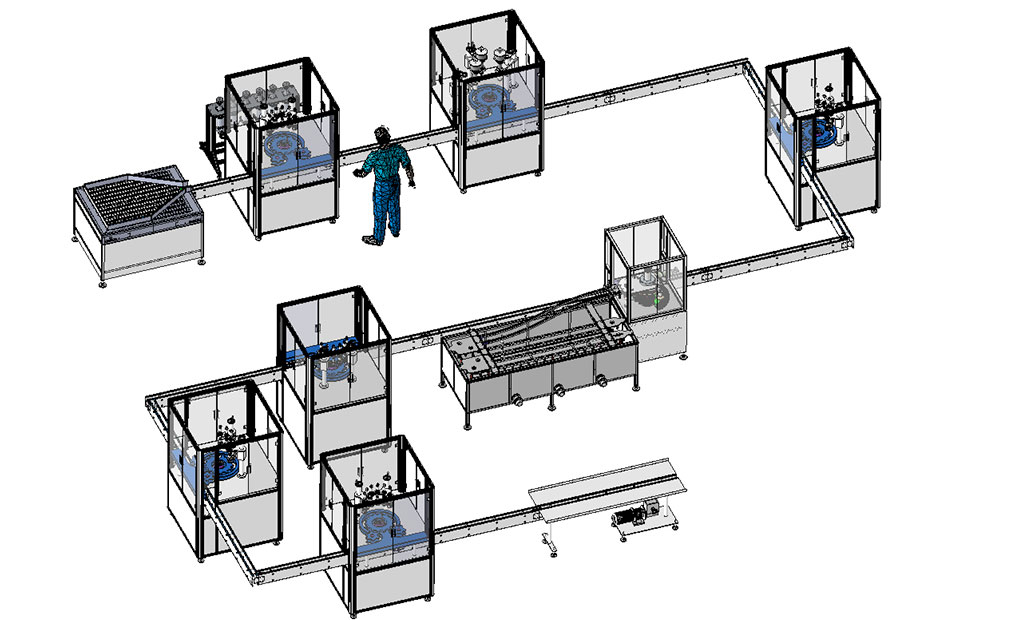

Aerosol Filling Machines Overview

Get Latest Price| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Transportation: | Ocean |

| Port: | Shanghai,Ningbo,Lianyungang |

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,CFR,CIF,EXW,FCA |

| Transportation: | Ocean |

| Port: | Shanghai,Ningbo,Lianyungang |

Model No.: Q-EY-4000P

Brand: Fuda

| Selling Units | : | Set/Sets |

Overall, aerosol filling machines play a crucial role in the packaging industry by automating the filling process and ensuring product quality and consistency. They are available in various configurations to suit different production requirements.Our company also has other productions including Automatic Aerosol Filling Machines、Semi-Automatic Aerosol Filling Machines、Measurement Instruments.

| Outline (L*W*H) | Capacity | Liquid Filling Volume | Gas Filling Volume | Accuracy |

| 22000*1500*2000mm | 30~45 cans/minute | 50~550ml | 0~0.6Mpa | ≤ ±1g |

| Applicable Can Diameter | Applicable Can Height | Applicable Valve Size | Working Air Pressure | Maximum Air Consumption |

| 40~66mm | 80~330mm | 1 Inch | 0.7~0.8Mpa(102~116Psi) | 4000L/M |

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.